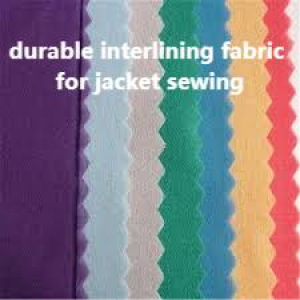

In the dynamic world of apparel design, Interlining plays a pivotal role in achieving structure, stability, and comfort across garments. The use of Interlining has evolved beyond simple reinforcement—it is now a crucial component in delivering the professional look, feel, and longevity demanded by modern fashion consumers. This invisible layer, though often unnoticed, transforms the ordinary into extraordinary by maintaining shape and drape while enhancing fabric performance across countless applications.

The Hidden Strength Within Garments

Behind every tailored jacket, crisp collar, and elegant dress lies an inner layer that ensures flawless construction. The precision selection and placement of this layer determine how the outer fabric behaves over time—retaining form, preventing wrinkles, and adding durability to high-stress areas. Without this essential support, even the most luxurious textiles would lose their refinement after just a few wears. Designers rely on advanced textile engineering to balance flexibility and firmness, ensuring garments maintain their visual and tactile appeal for extended use.

Evolution Of Textile Engineering

Modern material innovation has driven significant progress in garment construction. Advanced bonding methods, thermoplastic technologies, and improved fiber blending have enabled manufacturers to create layers that merge seamlessly with outer fabrics. These innovations reduce production complexity while enhancing comfort for the wearer. The evolution also reflects a broader trend toward performance-based fashion—where comfort, breathability, and adaptability are as vital as style. By applying refined engineering principles, manufacturers now ensure that every piece of apparel not only looks impeccable but also feels natural and durable.

Sustainable Approaches In Material Design

As sustainability becomes a cornerstone of the fashion industry, new developments are focusing on eco-friendly materials and production techniques. Textile manufacturers increasingly turn to recyclable fibers, low-energy bonding, and non-toxic adhesives to reduce environmental impact. Beyond reducing waste, these methods improve production efficiency, supporting global efforts toward greener manufacturing. Sustainability in textile support layers is no longer a niche concept but a competitive necessity that aligns with both industry ethics and consumer expectations.

Performance Beyond Aesthetics

While aesthetics remain a critical goal, performance defines the success of modern garment design. Advanced material layers enhance the wearer’s experience by improving moisture management, stretch recovery, and shape retention. In demanding environments—such as uniforms, sportswear, or high-fashion pieces—performance-enhancing fabrics maintain their integrity under stress. The unseen structural layer gives designers greater creative freedom, allowing complex silhouettes and lightweight designs to coexist without compromising durability or comfort.

The Future Of Global Textile Manufacturing

The future of garment innovation lies in synergy—combining scientific precision with artistic vision. As automation and digital textile technology evolve, manufacturers will continue developing smarter fabrics that adapt to body movement, climate, and usage. This fusion of technology and craftsmanship ensures that apparel remains both functional and expressive, setting new standards in global fashion. The journey of fabric transformation continues, led by companies dedicated to precision, sustainability, and human-centered design.To explore more insights and industry innovations, visit https://www.interlining-factory.com/news/what-is-interlining-types-applications-and-more.html